For Brad DeRoos, starting a high tech company was something he always wanted to do.

The deal, however, he made with his wife Liz was that their five children had to be out of the house and moving forward with their careers. (All five are graduates of West Virginia University.)

In 2013, DeRoos, a U.S. Naval Academy graduate and Naval Nuclear Engineer, did exactly that when he opened 4D Tech Solutions, the parent company of 4D Robotics and later, RedTail LiDar Systems. All three are headquartered in Fairmont in a former Fairmont Federal Credit Union building on 10th Street that DeRoos bought and remodeled when he relocated the companies from Morgantown last year.

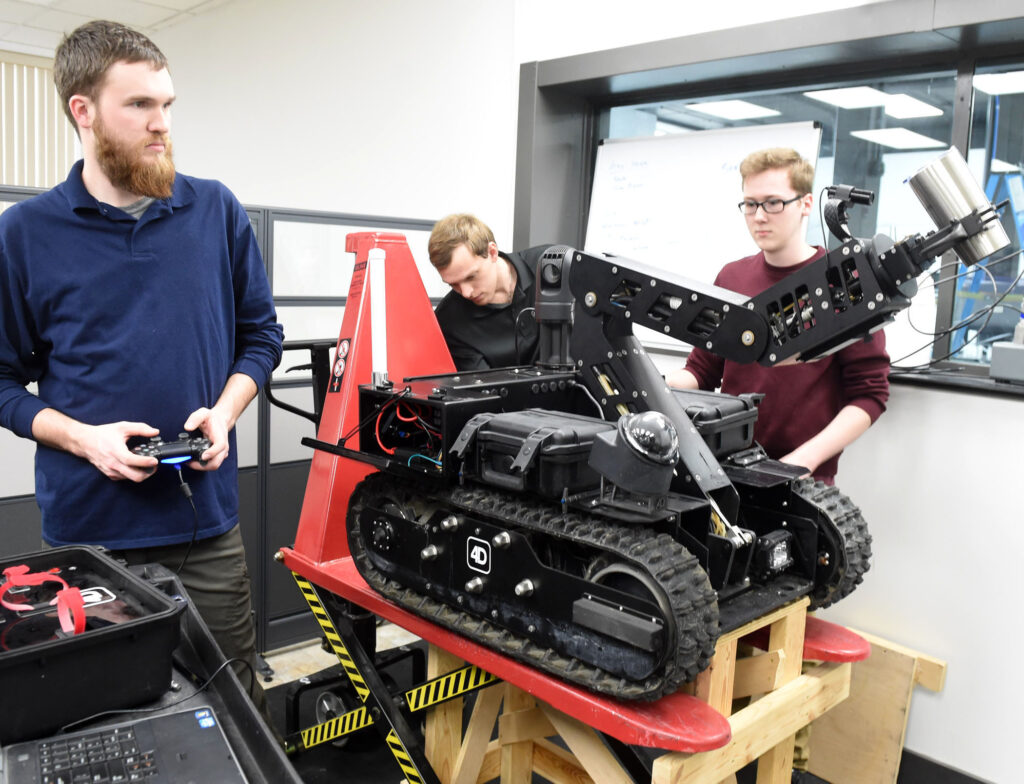

4D Robotics designs and manufactures robots that can be used in adverse conditions with the ability to life heavy objects, as well as the ability to be nimble enough to precisely move objects for customers, such as the U.S. government, law enforcement agencies and public safety organizations.

“It can open doors and even pick-up an egg,” said DeRoos of the robot dubbed MRV-1, which can lift up to 90 pounds. “You can operate it from a mile away.”

Matthew Bartrug (left) Mechanical Engineer at RedTail LiDar Systems operates the MRV-1 as engineer interns Tyler Plivelich and Gabriel Bobbitt look on.

The MRV-1 can navigate through 10 inches of water, go through mud and climb stairs, as well as hilly terrain. DeRoos, company president and CEO, said it was designed to be modular and can be kitted out for whatever mission is at hand.

RedTail LiDar, meanwhile, manufactures and designs a scanning system — think visual sonar — that can be attached to a drone. LiDar stands for light detection and ranging system, and it is made up of a laser, scanner and specialized GPS receiver. It can be used by the military for mission planning and execution, intelligence and surveillance.

“We’ve used it recently to survey a pipeline,” said Matthew Bartrug, a 4D Tech mechanical engineer.

The system developed by RedTail LiDar — a name chosen by company employees — weighs 4.7 pounds and can send back images from an altitude of 400 feet. It can also scan 400 lines a second and send back a 3-D image through its four separate lenses.

The RedTail LiDar technology was licensed from the U.S. Army Research Laboratory, the Army’s corporate research laboratory in Adelphi, Md. (The ARL’s mission is to discover, innovate and transition science and technology to ensure dominant strategic land power.)

The RedTail LiDar also has the ability to detect a half-inch difference in the soil. For example, a drone with the RedTail technology can be flown over a trouble spot in the Middle East, and then flown over again a week later. DeRoos said the LiDar will be able to detect whether an explosive device has been placed during the intervening days.

Since starting 4D Tech Solutions, DeRoos, who has been involved in high-tech start-ups in Ohio and has nine patents, said growth has been steady. But because most of the company’s contracts come from the government, the work flow can be uneven at times, he added.

DeRoos said his goal on the LiDar side of the business is to get involved with self-driving vehicles. The laser in the LiDar technology can be used to give cars the ability to see by sending out pulses that build a 3D model of the surrounding environment.

“It’s a growth industry,” he said.

Right now, 4D Tech’s immediate goals are to fine tune and enhance their existing product lines, such as making a lighter LiDar system and becoming a well-established Department of Defense contractor. DeRoos said he would also like to expand his current employee rooster of 16, but has no time frame.

One of the bigger obstacles 4D Tech faces as it grows, DeRoos said, is the distance from Washington, D.C., where many of his customers — and competitors — are located. He said he finds himself making the nearly 200-plus mile drive more often than he likes.

Still, DeRoos said he likes the people and the quality of life in Fairmont and the northcentral West Virginia region and has no plans to relocate.

Bartrug, a Fairmont native and WVU graduate, said he has the best of both worlds.

“I work with my hands,” he said. “I design and build and get to see things from start to finish. Drones and robots in West Virginia.”

Tweet @41Suzanne